Torch is a premier product designed to buffer and condition water used in pesticide applications. Whether applying a herbicide, insecticide, fungicide or bactericide, all products can potentially have a negative reaction with water. Most all of these products recommend an optimum solution pH for best performance, and many can react negatively with mineral elements that are in many of our water sources.

Torch is a premier product designed to buffer and condition water used in pesticide applications. Whether applying a herbicide, insecticide, fungicide or bactericide, all products can potentially have a negative reaction with water. Most all of these products recommend an optimum solution pH for best performance, and many can react negatively with mineral elements that are in many of our water sources.

As a grower you invest a large amount of money not only in your choice of pesticides, but in the crop itself. You apply pesticides for only one reason; to protect that investment and to obtain the highest economic return from your investment. Torch is an outstanding choice to ensure pesticide performance, thus offering even greater protection of your investment.

Following are excerpts from The Impact of Water Quality on Pesticide Performance, Purdue Extension Publication PPP-86, from Purdue University. This booklet is an excellent source of information, and is available at the Purdue Extension Store at a minimal cost, or is also available as a free internet download.

“Effective pesticide applications require attention to factors that influence product performance; product selection, label instructions, equipment calibration, and application timing. One factor that doesn’t get much attention is the quality of the water used to spray the product. Water often comprises ninety-five percent (or more) of the spray solution. What affect might it have on product performance?

Research clearly shows that the quality of water used for spraying can affect how pesticides perform. Its effect on product efficacy is reflected in the success of your spray operation. So why is it that we seldom notice something so obvious as the quality of water used in the spray tank? For the most part, water is viewed as a relatively clean input; if it runs clear, we don’t give much thought to its purity. Concise, easy-to-read information on how water quality affects pesticide performance is scarce.

What kind of problems can result from poor water quality? Water quality parameters such as acidity and dissolved minerals can interact with the active and/or additive ingredients of the pesticide product. Poor water quality can adversely influence the pesticide by reducing solubility and decreasing absorption by the target pest, resulting in inferior performance and the need for re-treatment.

Reduced product performance may not be obvious. In some cases, the influence of water on the pesticide reduces its effectiveness only slightly, yet enough that tolerant or tough-to-control weeds, insects, and diseases are not well controlled. Since water normally is used to deliver the chemical to the target pest, it should be considered the foundation for the application process.

Water hardness can affect some pesticides negatively. As in magnets, opposite charges attract: negatively-charged pesticide molecules attach to the positively charged iron, calcium, and magnesium (cations) in hard water. The binding of pesticides with these minerals creates molecules which cannot enter the target pest, or which enter at a much slower rate, or which can precipitate out of solution. The following cations, if they are present in water, can cause problems and may contribute to water hardness. They are listed in order of greatest potential to bind with pesticides: Aluminum, Iron, Magnesium, Calcium and Sodium.

Water pH. Pesticides normally are formulated as week acids or neutral to weakly-alkaline products. As a general rule, herbicides, insecticides and fungicides perform best in slightly acidic water, pH 4-6.5. Pesticides such as sulfonylurea herbicides perform better in water that is slightly alkaline (above pH 7.)”

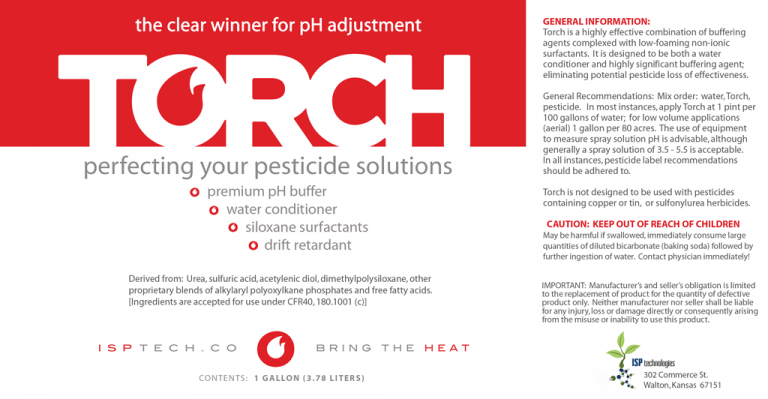

Torch addresses all aspects of proper pesticide application; water pH (buffering), and water conditioning by protecting chemistries from reacting with cations in the water. In addition, the active components of Torch are carried on the highest quality non-ionic siloxane surfactant available today, plus it also contains a drift retardant. Torch … the premium choice for ensuring pesticide performance!

Herbicide resistance is a problem that all of us are aware of, yet it still increases in severity. The same can be said for a number of the insect and disease issues responsible for millions of dollars of crop loss each year. Although we believe that the first line of defense against any pest is soil and plant health, we also realize that there are many instances where the use of a crop protection product is necessary.

Using multiple chemistries to battle the array of pests that either attack or compete with our crops is always recommended. Although this is an essential aspect of effective pest control, it also makes sense that when we do have to use a pesticide, weather to fight weeds, insects, or disease, that we chose a spray mixture that provides excellent control. All too often, we fail to not only rotate or change our chemistries, but also to ensure that what we do spray has optimum effectiveness. In short, we often create greater challenges for ourselves. We will use the same pesticide for multiple treatments, or we fail to consider the impact that our water has on the chemistries that we’re applying.

As mentioned, most pesticides are most effective when mixed into a solution that is somewhat acidic. Yet most all water is either somewhat, or highly, alkaline. Water pH and hardness can also change throughout a growing season, especially if using surface water such as ponds or rivers to draw the water for our spray solutions.

In early research we collected water samples from West Texas, Oklahoma, Kansas, Colorado, Missouri, Illinois, and Indiana. These 79 samples came from a variety of sources including city water, wells, and several ponds. The average pH of these samples was 7.73 prior to any treatment. When Torch was added at a rate of 1 part Torch to 1,000 parts water, the solution pH decreased to 2.58 , at a cost of $1.09 per point of pH decrease. This was both a significant and economical impact.

As awareness of the importance grew, the marketplace has become saturated with a large selection of buffering agents, conditioners, and other tank mix additives. So how do we know which is the best choice? We decided to do some additional research, and just see how effective some of the more common products worked. These results are illustrated in the graph, but it became obvious that even at a rate of 6.4 ounces of Torch per 100 gallons of water, the results were more pronounced than 32 ounces of other products per 100 gallons of water.

As growers, cost is always a factor in our decision making. When acquiring the other products we used in this project it became obvious that Torch was the most expensive product on a “per gallon of product” basis. Computing the cost of the product, and the effect on solution pH, it also became obvious that Torch was the most economical of all products tested.